SPI Lasers Discuss How Rapid Prototyping is Adding Real Value in Industry

May 15, 2015 (PRLEAP.COM) Business News

May 15, 2015 - Whilst rapid prototyping is certainly not a new technology, it is still one of the most important parts of manufacturing today. Rapid prototyping technology adds real value to a wide range of industries, which one may not even have ever thought of.Benefits of rapid prototyping

Rapid prototyping enables manufacturers to deliver complex and precise prototypes. Physical models, made through prototyping can convey ideas to collaborators, clients and marketers in ways computer models cannot. Rapid prototyping therefore assists with communicating ideas clearly and gaining detailed feedback.

Another benefit of rapid prototyping is cost reduction. This is achieved in a number of ways such as wastage reduction, tooling cost reduction and production cost reduction. This process enables manufacturers to discover faults in their designs at the earliest interval, therefore allowing them to fix problems before they become costly issues. The fact rapid prototyping also allows designers and manufacturers to make more revisions in less time ensures they can send high quality products to market on a stricter timescale.

A final benefit of rapid prototyping is that it enables manufacturers to know exactly how their product will look and perform before they have even invested in tooling.

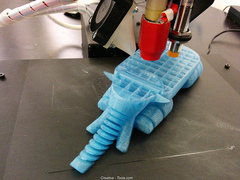

Today a wide range of 3D printing materials can produce highly functional prototypes, which allows for accurate performance testing. With rapid prototyping, there is the opportunity to create a realistic model that looks and feels like the finish product, which can be highly beneficial for both designers and manufacturers.

Rapid prototyping processes

There are a number of different processes that are carried out in order to create rapid prototypes. One of the most popular processes is 3D printing (also known as additive manufacturing). This involves printing out layers of a material, which are built up to make a 3D object. The most common materials used for 3D printing include wax and thermoplastics. This innovative rapid prototyping technology enables designers to create shapes and designs of all complexities.

Laser sintering is another form of rapid prototyping. This process involves using a laser to melt a cross section of the design in a layer of powdered material. It then hardens on the top of previous layers and slowly builds up the shape of the product. The individual layers may be extremely thin but together they create a strong prototype that can be fully tested for accuracy.

Another rapid prototyping process is stereolithography. This process involves using a laser to scan a bath of photosensitive resin. When the laser scans the surface, the liquid solidifies the cross section of the design and then moves to the next layer. A 3D model is then slowly built up below the surface of the liquid.

Other key rapid prototyping processes include fused deposition modelling (FDM), laminated object manufacturing and solid ground curing.

Rapid prototyping materials

All sorts of materials can be used in rapid prototyping, giving designers and manufacturers the opportunity to create prototypes for a wide range of products. Some of the most popular materials used for rapid prototyping include metal powder, paper, plastic, polymers, wax and food.

Rapid prototyping and its value to industries

One of the great things about rapid prototyping is that it's very versatile, meaning that a wide range of industries can use it to assist them in manufacturing their goods.

Automotive is one example of an industry that uses rapid prototyping. In fact, the Ford Motor Company has found that using rapid prototyping techniques allows them to save millions of pounds each year, compared to traditional manufacturing techniques.

Businesses in the food industry also use rapid prototyping to assist them in designing and manufacturing packaging. Saarioinen, a leading food producer in Finland recently commissioned an additive manufacturing company to design and build 3D printed prototypes for their new line of source bottles. The aim was that they would be able to test the behaviour and durability of the sauce bottles in a more time and cost effective way than if they were to use a conventional prototyping method.

Even companies in the medical industry now use rapid prototyping to keep their costs to a minimum. Instrumentation Laboratories manages to save around $600K per year by using FDM rapid prototyping, rather than traditional manufacturing methods.

A valuable technology

Even decades after it was first introduced, rapid prototyping still plays a crucial role in manufacturing across a wide range of industries. From helping companies to test their ideas and keep costs to a minimum to speeding up production times, rapid prototyping has a lot to offer and therefore adds real value to a wide range of industries. For more information about the benefits of metal rapid prototyping visit the SPI Lasers website www.spilasers.com.

Contact information

SPI Lasers (UK) Ltd

Phone: +44 (0) 1489 779 696

Email: sales@spilasers.com

Address: Cosford Lane

Swift Valley

Rugby

CV21 1QN

United Kingdom

Image credits: Creative Tools and Creative Tools