VAC-U-MAX Answers Tough Pneumatic Conveyor Questions at Pack Expo 2011

August 22, 2011 (PRLEAP.COM) Business News

Belleville, NJ, August 22, 2011 – For answers to your tough pneumatic conveyor problems or industrial vacuum cleaning solutions that comply with OSHA's Combustible Dust program, booth 5121 is the place to be at PACK EXPO 2011 at the Las Vegas Convention Center, September 26-28."Rather than getting into a lot of gimmicks at these trade shows, we look at them as a place where we can roll up our sleeves and brainstorm solutions for our clients," says Doan Pendleton, VP of Marketing and Sales at VAC-U-MAX.

Users of vacuum conveying equipment often assume they need a custom, one-of-a-kind solution when their application actually calls for a pre-engineered product that offers option capabilities that best fit their application.

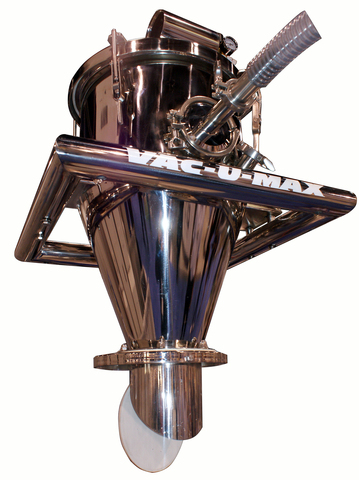

From innovative systems for food packaging and reloading applications as well as pharmaceutical applications such as Tablet Press Loading systems that are complete, ready-to-operate pneumatic conveyor systems, VAC-U-MAX combines modern electronic technology with innovative mechanical and pneumatic design to customize pneumatic conveyor systems that perform sophisticated operations with little human assistance, deliver flexibility, integration and efficiency that have long been sought after.

Some of the conversations overheard at the VAC-U-MAX booth at PACK EXPO 2010 addressed how to economically introduce an organic line into production; how to use the distribution feeder to distribute poppy seeds and nuts evenly across product; solutions for conveying and packaging salt; how to make adjustments in conveying lines to preserve product integrity; and, how to improve housekeeping and comply with OSHA's Combustible Dust Emphasis Program.

Sometimes processors think that pneumatic conveyor systems are tough on materials because they have heard from other people that it will deteriorate their finished product. "Pneumatic conveying equipment is gentler than people think. Think of something as delicate and precise as medicinal tea—we have designed pneumatic conveying systems for medicinal tea manufacturers that produce more than 2 million bags of tea per week," says Pendleton.

With an ever-increasing intensity to improve manufacturing operations a growing number of processors are turning to customizable ready-to-go pneumatic conveying systems that are pre- packaged to deliver flexibility, integration and efficiency to their operation.

The primary technology for conveying is vacuum, but positive pressure pneumatic systems as well as mechanical conveyors, such as flexible screw conveyors, are used as applications dictate.

"If people want answers to problems they have on the line, or want to increase production, or reduce labor intensive processes, they should stop by the booth and talk to us. More than likely we have dealt with a problem that is similar to theirs and can come up with a solution that fits their specific needs," says Pendleton.

In addition to nearly 60 years of experience providing solutions for conveying, vacuum conveying, batching, and weighing materials to the pharmaceutical, food, and chemical industries, VAC-U-MAX has a fully functional state-of-the-art 6000-sq-ft test and demonstration facility where they can simulate the actual conditions at a customer's site.

To get answers about using a pneumatic conveyor for bulk powders and solids or industrial vacuum cleaning solutions, visit VAC-U-MAX in booth 5121 at PACK EXPO 2011, or write to them at 37 Rutgers Street, Belleville, NJ 07109; call 1-800-VAC-U-MAX (800-822-8629); e-mail info@vac-u-max.com; or visit their website www.vac-u-max.com.