7 x 7 x 7 = $5,000,000? AFuzion's Avionics Development Tips save Japan $5M

March 07, 2017 (PRLEAP.COM) Business News

March 7, 2017 - Avionics development is never cheap but done right it can be both cost-effective and profitable. Seven AFuzion avionics software engineers recently completed a 7-month assignment in Japan on the new Mitsubishi Regional Jet. Their worked saved the Japanese client over $5,000,000 by applying seven important tips, provided here.Says Mr. A. Morita (AFuzion's Japanese Client) "We are very pleased to acknowledge the success of AFuzion's expert engineers and DER's. Half the work needed to be done onsite in Japan and the AFuzion engineers were very hard working and productive. The other half could be done offsite by AFuzion in USA and it was good also. Our engineers traveled to California and worked in AFuzion's Los Angeles offices; it was very nice and productive. The AFuzion avionics engineers gave us DO-178C training and also DO-178C and DO-254 best practices. The AFuzion DO-178C gap analysis was good and helped us understand the gaps. Our only wish is that we engaged AFuzion sooner as we could have save even more money and time."

AFuzion's Mr. Jack Jones states "I managed the onsite AFuzion Japan engineers plus three of our DER's and was there for the entire 7 month engagement. It is really a pleasure working with the Japanese as they are hard-working and diligent. The Japanese culture is well-suited to successful avionics because DO-178C and DO-254 require diligence, skill, and plenty of checklists; we used the new 2016 AFuzion DO-178C and DO-254 checklists and they're really great – note the lessons below. I think we'll be seeing much of Japanese aviation and avionics engineers in the future – we're quite impressed and as you know AFuzion engineers aren't easily impressed. At the successful conclusion, we were."

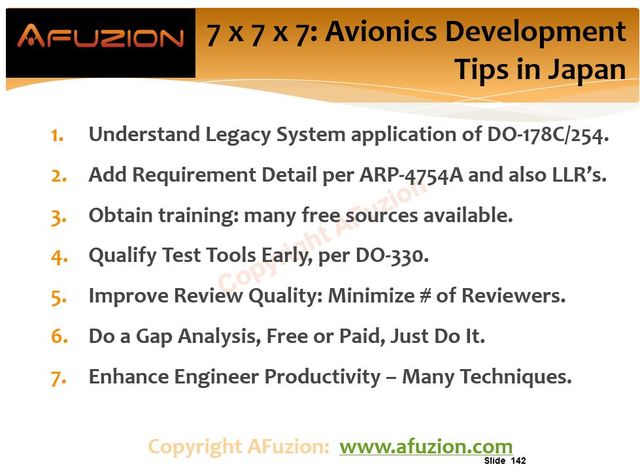

Here are the top 7 avionics development tips from AFuzion's seven developers in Japan for seven months:

#1). Understand that aviation and avionics are not "all-new" developments, but that there is much legacy foundational work. While DO-178C and DO-254 seem to "presume" all-new custom development, the truth is that most avionics projects are upgrades to existing legacy systems and a combination of previously developed hardware/software, and reverse-engineering applies. Read CAST-18 about Reverse Engineering for avionics (request a copy at www.afuzion.com or download the Top DO-178C Mistakes whitepaper at Avoiding DO-178C's Top Mistakes and Reducing DO-178C Costs

#2) Go back and focus on requirements. For system requirements, be sure to apply ARP-4754A but understand ARP-4761. Get ARP-4754A training or at least read up on it (for a free introduction, just download and read "Understanding ARP-4754 Introduction" here: ARP-4754A Tutorial

Be sure to address Safety requirements and prove your Systems engineers reviewed this and QA audited it (note: this wasn't done when AFuzion first showed up onsite so we quickly had to rectify that) Go back and add more detailed DO-178C and DO-254 requirements. Address derived requirements explicitly. Use a detailed requirement review checklist (request a free copy from AFuzion if you don't have one).

#3. Get good DO-178C training, ARP-4754A training, or DO-254 training. If you can afford outside trainers, just Google and find the best (that's easy – AFuzion's engineers did the world's first 30 years ago and have trained over 12,000 worldwide; over 1500 in just the past year). If you can't afford outside training, read the books on DO-178C and DO-254 and download the recent whitepapers (most were all written by AFuzion but AFuzion's old ones are available from Atego and HIghRely; best to get the new ones (all free from AFuzion) and compare with the old ones our engineers wrote 15 years ago which are nicely still provided by Atego and HighRely – you can see how much avionics has changed in those 15 years and how NOT to do things by reading the latest versions; only available from AFuzion). Also for free: a one hour seminar on DO-178C Mistakes – watch here for free: DO-178C Training Synopsis Webinar- Free

#4. Qualify your test tools. When AFuzion's team first arrived in Japan, the engineers there were working hard re-reviewing all the code and tests manually, repeatedly. Everything was changing and the amount of time spent on re-reviews was enormous. We taught them how to instead perform DO-330 tool qualification to avoid re-reviewing all the code and tests repeatedly. This alone saved our client over $500,000 in those seven months and probably $2-3M over the future lifetime. If you don't know how to do DO-330 tool qual, just download a free DO-330 Tool Qualification paper here: DO-330 Introduction Whitepaper

#5. One great reviewer is better than many good reviewers. When we arrived in Japan, the well-intentioned customer engineers had 5-10 reviewers at every peer review. Massive overlap but also some gaps. Instead, use professional checklists (AFuzion has the world's latest and most thorough DO-178C checklists and also DO-254 checklists; not just the old rehashed open-source checklists from Boeing's D6 document which everyone else sells, but real all-new DO-178C and DO-254 checklists). Train reviewers to do complete reviews; if you can, use Agile DO-178C methods and CMMI review methods. Make sure you capture the transition criteria for reviews and that QA audits those review transition criteria. And always use one great, responsible and accountable reviewer instead of numerous weak reviewers.

#6. Do a DO-178C gap analysis and DO-254 gap analysis. Leverage 60-70% of your existing work and artifacts and keep them! No need to change. But understand the gaps and close them. If you can afford it, engage a professional gap analysis like this one: DO-178C & DO-254 Gap Analysis Information If you can't afford an outside gap analysis, get training and do your own. At least understand common mistakes and avoid those. For example, here's a free paper on how to avoid common DO-254 mistakes: Avoiding DO-254 Mistakes

But remember to keep review records of your reviews (again our Japanese client had great reviews but simply didn't have great records to prove that).

#7. Reward productivity. Some engineers are 500% more productive than others. Because they're smarter? Probably not – our Japanese client engineers were all exceptionally smart. But teach productivity and reward it. Make competition fun. We gave weekly "bonus recognition" awards of a trip for two to the local sushi house on Saturday – many pounds of tuna were indulged in engineers who increased their productivity. At the end, everyone was much smarter, more productive and really enjoying work; three of our engineers will remain through 2017 and likely beyond.